Flexo Printing Sleeves

Please contact ScanTeco for further information

Tech sleeves® offers customized sleeve solutions for the flexographic printing industry. They believe that they can increase the printing quality and overall efficiency through a combination of experience and innovation. Their vision is to continuously develop products that enhance performance and quality while offering innovative features and services to strategically position the company worldwide.

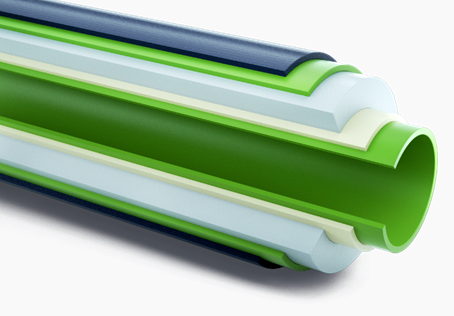

Understanding the problems in the industry, they use unique high-quality materials to ensure durability, consistency and dimensional stability. All their flexo printing sleeves and bridges are built with different layers:

Innermost core

Flexible and expandable innermost core. (1 mm)

Contains Dyneema® that offers maximum strength with minimum weight.

Dyneema® doesn’t fray and is up to 40% stronger than aramid fibers such as Kevlar®.

Prevents slipping of the sleeve on the mandrel.

Extremely durable and resistant to moisture, UV light and chemicals.

Foam Layer

Compressible Foam Layer. (1 mm )

The compressible Foam Layer has high rebound resilience and is up to 50% compressible without bulging.

Reduces bouncing and enables the sleeve to have a perfect fit on the mandrel.

Resistant to permanent deformation, good abrasion resistance from aging, weathering and cleaning solvents used for polymer plate cleaning.

Tech core

Stitched, Bonded and Compressed Tech core material in various thicknesses.

Contains a filament fiber base which is volumized by fiberglass infused with Epoxy Vinyl-Ester-Resin.

Light weight with extreme high flexural strength and form stability.

Ultra-high-strength composite core reduces bouncing at high speed.

Outer Surface Layer

The Outer Surface Layer contains Epoxy Vinyl-ester-resin reinforced with technical filaments and polyester fleece. (2 mm.)

High chemical and temperature resistance with excellent tape mount and demount properties.

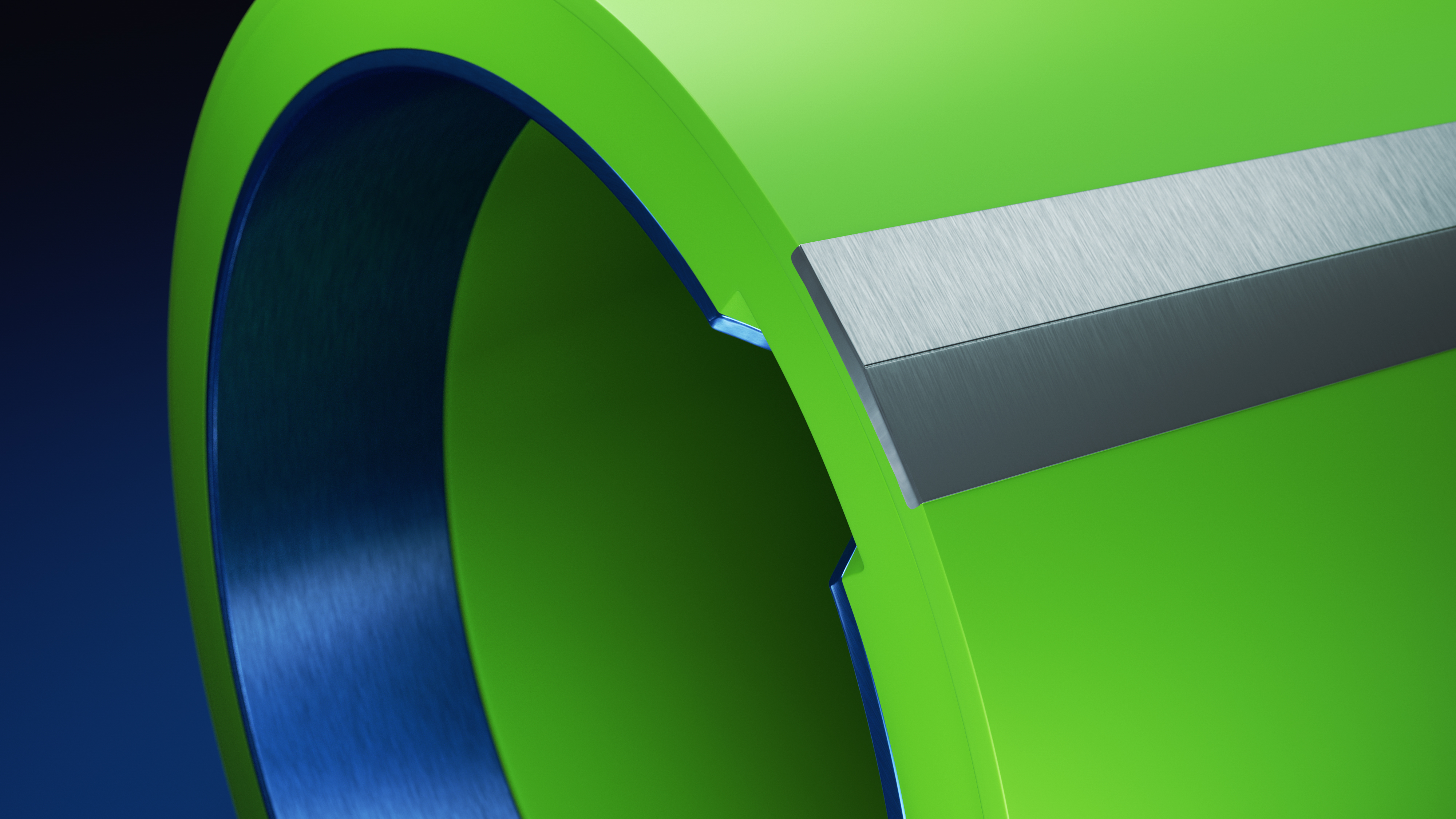

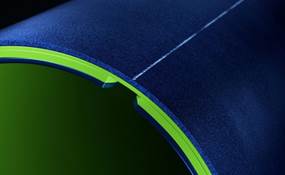

Outer compressible surface layer

The compressible surface layer for compressible soft sleeves and bridges consists of cellular, water crossed-linked foamed polyurethane.

The outer layer of the soft sleeves / adapters is available in 40, 50 or 60 ShA.

Designed to eliminate the need of compressible double sided mounting tape.

Saves time and money on tape because of its compressibility.

- Home

- About

- Machinery

- Equipment

- Air expanding & Friction shafts

- Alu. – Steel & Carbon Rollers

- Ancillary equipment

- Anilox & GTT Sleeves & Rollers

- Doctor Blades

- Flexo Printing Sleeves

- Gravure Printing & Coating

- Knives

- Offset

- Pumps, Tanks, Stirrers, etc.

- Slitting Systems

- Viscosity Control & Controls For Coating

- Web cleaning, antistatic control & ESA

- Web Guiding & Tension Control

- 100% Defect detection

- Consumables

- Spare Parts

- Used Machinery

- Technical Service

- Partners

- Contact